Gain access to personalized product screening, the best pricing, rewards, and more!

Most Effective Products

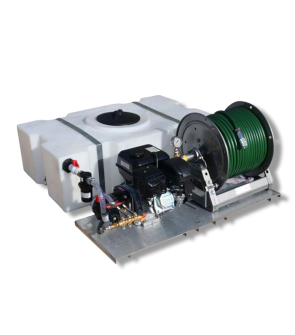

Professional Pesticide Application Equipment

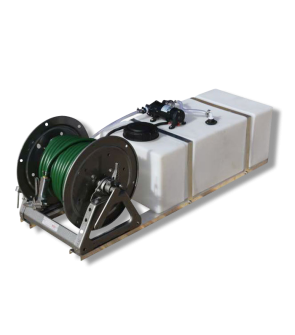

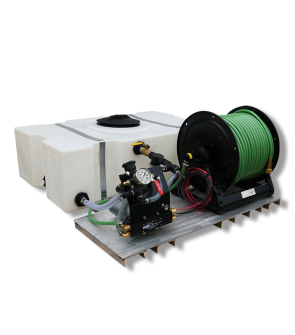

Pest control equipment are designed to make the application of chemicals for pest control easier, more convenient and less labor-intensive. The right equipment can also make things safer for applicators and the overall environment. If you’re not a professional, you should only act under the guidance of properly laid out instructions, preferably from pest control experts like us.

Solutions Pest & Lawn carries a full stock of tested, durable, professional pest control and lawn care equipment which are easy to use. Our warehouse contains wholesale pest control supplies and equipment developed by leading manufacturers such as Solo, B&G, MistAway, Curtis DynaFog among others.

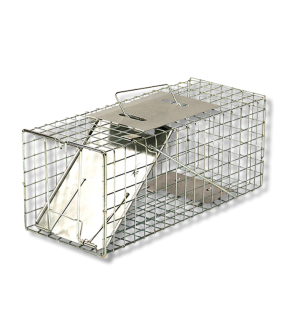

Browse this section to find professional-grade hand-pump sprayers, power sprayers, backpack sprayers, dusters, animal traps, safety equipment, bee suits, and everything else you need to get the job done right. We aim to provide pesticide and herbicide equipment and other types of professional-grade supplies at the lowest prices you can find on the market.

Recommendations

There are many factors to decide on when picking out what pest control equipment you need. While what you choose may vary depending on the type of problem you have, where you have the problem, and what method of treatment product is the best solution, here we will break down the most basic necessary items needed when conducting general pest control around your home or commercial property.

Solutions 1 Gallon Poly Sprayer

Whether you are using an insecticide product, a fungicide or a herbicide, you need to store and mix the product in a proper container and disperse the mixture efficiently. Our pump sprayer comes with a gallon tank which make it easy to pour in, agitate and mix the solution and also comes with a convenient adjustable wand so you can customize the way you want the product sprayed out. This sprayer is built to last a long time.

Hose End Sprayer

When spraying around your lawn and garden for weeds, pests or fungi, a hose end sprayer is ideal. There's no need to lug around heavy amount of mixed product in a tank, nor do you need to pre mix solutions. This saves time and makes applying product hassle free. Hose end sprayers are also better when it comes to reach as they are great for spraying upwards on tall foliage and exterior part of your home structure.

Handheld Pesticide Duster

Dust pesticides are one of the best methods of indoor pest control as the product is able to safely reach where insects are hiding in cracks and crevices and voids. However, if you're using the dust applicator tip that comes with the dusting container, you may have a frustrating time. That's why a handheld pesticide duster is a must-have so you can conveniently disperse the dust in a precise manner where you need it.

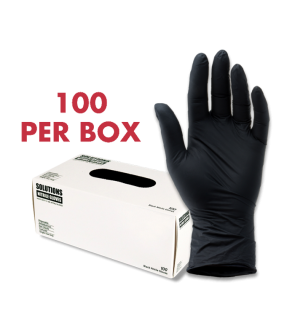

Homeowner Chemical Safety Kit

Safety first! Before mixing or handling any chemicals, it is a must to protect your eyes, ears and breathing passages with PPE. This safety kit comes with all that you need (goggles, gloves, face mask) to be able to safely conduct chemical treatment applications.

User Guide

Solutions 1 Gallon Poly Sprayer

Mixing the Solutions 1 Gallon Poly Sprayer is easily. Simply dilute the product you are using with water in the sprayer tank, referring to the product label for specific amounts. Agitate the sprayer to ensure the water and product is well mixed and then pressurize the sprayer with a few pumps of the handle. After that, you are ready to spray. Simply depress the spray button found on the wand. Be sure to set your spray tip to the desired setting which can either be a cone jet as well as a pin stream spray.

Hose End Sprayer

Hose end sprayers conveniently do not require any pre-mixing. Simply fill the reservoir to the required level to produce the desired amount of spray and then attach the sprayer to a garden hose securely. Once the sprayer is filled and secured to the end of your garden hose, turn on the water pressure, point the sprayer were you would like to spray, and push the thumb switch to the ON position. The sprayer will mix the product with water as you spray.

Handheld Pesticide Duster

Remove the metal cap from the reservoir and begin filling the duster with your chosen insecticide dust, making sure not to fill it too much. Direct the delivery spout where you intend to treat, such as inside cracks or crevices, under kitchen appliances, along baseboards at the edge of carpeting, or in wall voids. Squeeze the reservoir to apply small puffs of dust.

Homeowner Chemical Safety Kit

The homeowner safety kit comes with gloves, protective goggles, and a dust particle mask. Place these items on before carrying out any chemical mixing or application to protect yourself from potential accidents.

Inspection and Maintenance

If you want your equipment to last for the long haul, regular maintenance and inspection of parts is important. To make sure you don’t miss anything, take a structured approach of developing your equipment management program. Our general suggestions below are a basic way to examine and address issues in the fundamental parts of our pest control spraying equipment.

Solutions 1 Gallon Poly Sprayer

Clean your spraying tank periodically to clear out any chemical buildup and debris. Depending on the types of chemicals and formulations of the pesticide products, they can potentially clog lines and make it difficult for your tank to function properly. Most pumps will sustain serious damage if they run dry.

Hose End Sprayer

Due to the simple construction of the Chapin 20 Gallon Hose End Sprayer very little maintenance is required. Take care to ensure that you empty the reservoir with each use, and rinse the unit out before leaving it in an open area to dry. Store the unit in a cool, dry place between uses.

Handheld Pesticide Duster

Visually inspect your duster to ensure that it is working properly. Occasionally dusters will clog and that's why it comes with a ball bearing to place in the duster to break up dust to fix clogging issues. When not in use, store the duster in a cool, dry place.

Homeowner Chemical Safety Kit

When it comes to the gloves in the kit, check to ensure there are no rips, tears, or other damage that could allow chemicals to pass through and make contact with your skin. For eye protection, make sure there is no damage and ensure any straps or fasteners are in good condition. In the case of respirators or masks, inspect filters, if any, and replace if needed.

Parts

Solutions 1 Gallon Poly Sprayer

Handheld Pump Sprayers consist of the pump, the reservoir, the hose, the wand, and the spray tip. The pump is what pressurizes the sprayer to efficiently spray the mixed product. The reservoir houses the mixed pesticide product. The hose is what transfers the mixed solution in the tank to the spraying wand for application and the spraying tip (which is adjustable) is what focuses the spray. The tip can be adjusted to different settings such as a pin stream, cone-shaped or fan spray.

Hose End Sprayer

The Chapin 20 Gallon Hose End Sprayer consists of the reservoir, the fitting, the fingertip on/off control, and the nozzle. The reservoir holds the pesticide concentrate. The fitting is what attaches to a garden hose. The on/off control is a switch flipped to allow water to be mixed with the pesticide before spraying out and finally, the nozzle is where the spray solutions come out.

Handheld Pesticide Duster

It has an internal spring system that allows the applicator to apply dust while holding the duster at any angle, a reservoir for dust, 6.5-inch long delivery spout, and a plastic end cap that covers the delivery spot to prevent dust waste and leakage.

Homeowner Chemical Safety Kit

The homeowner safety kit comes with gloves, protective goggles, and a dust particle mask.

Part Replacement

In addition to our offerings of pest control equipment and wholesale pest control supplies, we offer hard-to-find equipment parts and accessories to replace older equipment parts that have been worn down. Why hurt your budget by buying an entirely new piece of equipment when you can simply replace broken down parts and get it up and running again? Solutions carries these parts to save you time and money so you can get the most out of the equipment you purchase from us.

Key Takeaways

- At Solutions Pest & Lawn, we offer the highest-quality pest control, wholesale pest control supplies and lawn care equipment and parts on the market at extremely affordable prices. These are not items that you will find at your local big-box store. When you want the right stuff for your pest control treatments, Solutions is the best choice.

- Equipment maintenance is key to its longevity. Make sure to check components of pest control products such as line strainers (filters), motors, belts, hoses, nozzles, etc. before starting equipment. This will help to identify any issues with your equipment and address them before the problem worsens.

- Inspect and maintain your equipment regularly and order replacement parts when necessary.